HUAQI ZHENGBANG

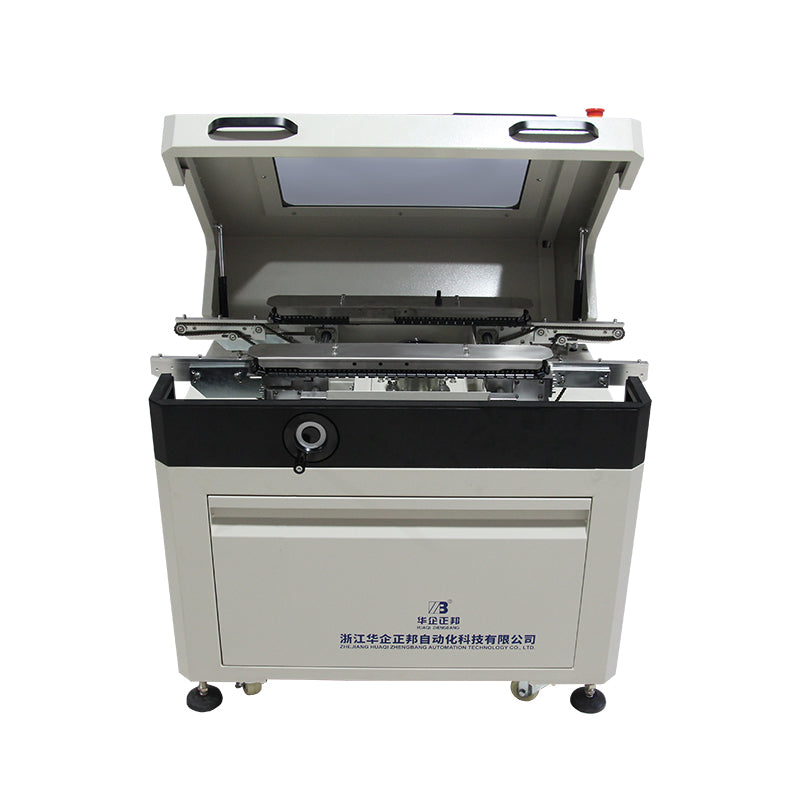

ZB250QE Automatic PCB Lead Cutting Machine for THT Production Line

The ZB250QE Automatic PCB Lead Cutting Machine is engineered for efficient trimming of excess component leads in through-hole (THT) production. With its high-precision cutting system, durable structure, and fully automated operation, it significantly improves production efficiency while ensuring clean and consistent lead-cut results for various electronic assemblies.

Key Features

-

High-Precision Lead Cutting System

Equipped with a robust rotary blade mechanism to cut component leads quickly and cleanly without damaging solder joints or PCBs. -

Automatic PCB Feeding & Processing

Supports continuous automatic loading and unloading, reducing manual handling and improving productivity on THT lines. -

Adjustable Cutting Height

Cutting height can be fine-tuned to meet different PCB thicknesses and lead lengths, ensuring optimal consistency. -

Wide Compatibility

Suitable for single-side and double-side assembled PCBs. Compatible with various fixture types and THT production workflows. -

Durable and Stable Structure

Heavy-duty frame and vibration-resistant mechanical design ensure smooth operation under long-term, high-volume conditions. -

User-Friendly Interface

Simple and intuitive control panel for easy operation, parameter adjustment, and maintenance. -

Enhanced Safety Protection

Includes emergency stop, protective covers, and overload protection for safe industrial use.

Applications

-

THT PCB production lines

-

Consumer electronics

-

Home appliances

-

Automotive and industrial control boards

-

Power supplies and adapter boards

-

Any production requiring efficient post-solder trimming of excess leads

Professional Service

Everyone has many years of international trade experience, we communicate with customers in time and earnestly